We are transparent on what we use to build a better quality concrete mixture for you.

CAPACITY

TECHNOLOGY

QUALITY

60 cu.m/hr equipped with SCHWING STETTER Twin shaft mixer

MCI 550 control system with SCADA software that has numerous features.

HIGH-TECH lab facility with experienced technicians & examines for operations & quality analysis

CAPACITY

60 cu.m/hr equipped with SCHWING STETTER Twin shaft mixer

TECHNOLOGY

MCI 550 control system with SCADA software that has numerous features.

QUALITY

HIGH-TECH lab facility with experienced technicians & examines for operations & quality analysis

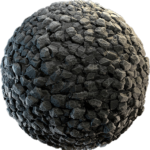

10MM

Sourced from quality quarries, our 10mm aggregate is ideal for high-strength concrete mixes, providing excellent durability and workability.

20MM

Our 20mm aggregate offers robust support for large-scale construction projects, ensuring superior strength and long-lasting structural integrity.

Zone 2 Sand

Our Zone 2 sand is meticulously graded for optimal use in concrete and plastering, enhancing both the texture and finish of the final product.

Flyash

Chavda RMC uses high-quality fly ash to improve the performance of concrete, ensuring greater strength, reduced permeability, and enhanced sustainability.

RAW MATERIALS

Our Crushed Aggregate feature is ideal for use in construction work. Used as a raw material in the production process, Raw materials that we use offers excellent properties with ultra-smooth surfaces resulting in an outstanding surface finish. Utilized extensively by the construction industry for its ability to act as a dust suppressant and carrier medium in finished goods production processes.

NON VSI - VERTICAL SHAFT IMPACTOR

VSI - VERTICAL SHAFT IMPACTOR

- Sieve analysis Test are not nessesarily as per indian standard norm.

- Non VSI Aggregate are generally flaky and Elongated.

- Non VSI is most preferred in Nominal Grade of concrete.

- Decrease workability as aggregate are flaky, elongated Etc.

- Non VSI Aggregate have no uniform surface which affects bonding.

- NON VSI Aggregate have some amount of dust.

- When Non-VSI materials are used in concerete the compressive strength decrease 4 to 3 N/mm2. against VSI. as the aggregates are flaky, elongated & Irreguar in shape.

- VSI aggregate are usually dust free.

- Sieve analysis test are as per india standard norm.

- VSI Aggregate are mostly Cubical in shape

- VSI is most preferred in higher grade concrete.

- Increase workability as aggregate are cubical.

- VSI Aggregates have better surface and good bonding.

- When VSI materials are used in concrete the compressive strenth increase 3 to 4 N/mm2. against Non-VSI. as the aggregates are consistent.

NON VSI - VERTICAL SHAFT IMPACTOR

VSI - VERTICAL SHAFT IMPACTOR

- Sieve analysis Test are not nessesarily as per indian standard norm.

- Non VSI Aggregate are generally flaky and Elongated.

- Non VSI is most preferred in Nominal Grade of concrete.

- Decrease workability as aggregate are flaky, elongated Etc.

- Non VSI Aggregate have no uniform surface which affects bonding.

- NON VSI Aggregate have some amount of dust.

- When Non-VSI materials are used in concerete the compressive strength decrease 4 to 3 N/mm2. against VSI. as the aggregates are flaky, elongated & Irreguar in shape.

- VSI aggregate are usually dust free.

- Sieve analysis test are as per india standard norm.

- VSI Aggregate are mostly Cubical in shape

- VSI is most preferred in higher grade concrete.

- Increase workability as aggregate are cubical.

- VSI Aggregates have better surface and good bonding.

- When VSI materials are used in concrete the compressive strenth increase 3 to 4 N/mm2. against Non-VSI. as the aggregates are consistent.

NON VSI - VERTICAL SHAFT IMPACTOR

- Sieve analysis Test are not nessesarily as per indian standard norm.

- Non VSI Aggregate are generally flaky and Elongated.

- Non VSI is most preferred in Nominal Grade of concrete.

- Decrease workability as aggregate are flaky, elongated Etc.

- Non VSI Aggregate have no uniform surface which affects bonding.

- NON VSI Aggregate have some amount of dust.

- When Non-VSI materials are used in concerete the compressive strength decrease 4 to 3 N/mm2. against VSI. as the aggregates are flaky, elongated & Irreguar in shape.

VSI - VERTICAL SHAFT IMPACTOR

- VSI aggregate are usually dust free.

- Sieve analysis test are as per india standard norm.

- VSI Aggregate are mostly Cubical in shape

- VSI is most preferred in higher grade concrete.

- Increase workability as aggregate are cubical.

- VSI Aggregates have better surface and good bonding.

- When VSI materials are used in concrete the compressive strenth increase 3 to 4 N/mm2. against Non-VSI. as the aggregates are consistent.

Our Machineries Specification

Truck Mixer

- High cu.m concrete carrying capacity.

- High loading volume and optimum drive characteristics.

- High loading volume and optimum drive characteristics.

Wheel Loader

- 2.1 cu.m Bucket carrying capacity.

- Strong and reliable power train Z-bar linkage for greater digging power.

- 130 Kn of bucket breakout force.